Early in my sterile processing career I encountered a concept that has been a pivotal force in building trust among frontline technicians, cultivating high-performing departments, and ensuring my underlying vision for leadership never missed the mark. I call the concept the Triangle of Truth, and if you haven’t heard of it before, it might change the way you approach the everyday problems in your department and give you critical insight into why some of your current challenges haven’t gone away.

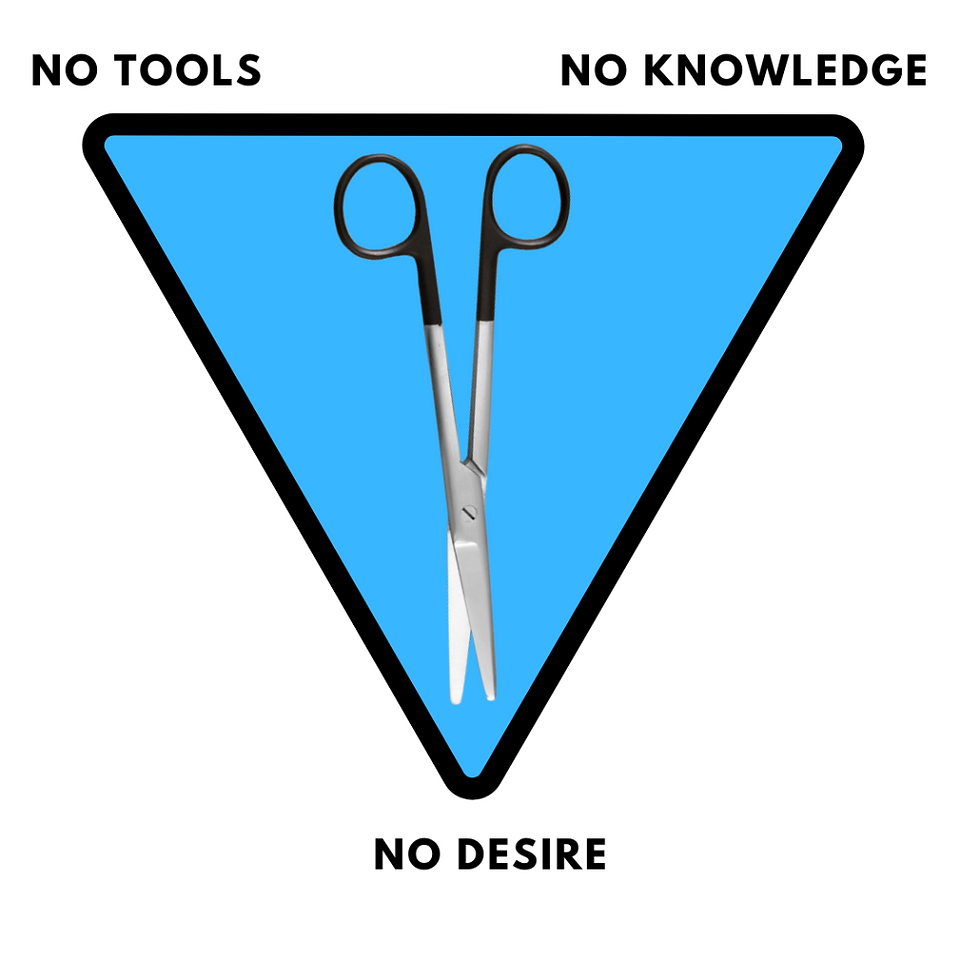

What is the Triangle of Truth? The best way to describe the Triangle of Truth is that it acts as a filter to enable anyone from frontline technicians to department leaders and administrators to quickly pinpoint root causes for certain issues in sterile processing. It is comprised of three points:

No Tools – individuals or the team lack proper equipment to complete the process or task, also known as “can’t do it”

No Knowledge – individuals or the team lack proper knowledge and training related to compliantly or efficiently completing the process or task, also known as “don’t know how to do it”

No Desire – individuals or the team lack the willingness to complete the process or task compliantly or efficiently, also known as “won’t do it.”

Let’s go through three different scenarios to see how it works in real life.

No Tools: On expectations and equipment (scenario 1) You keep getting bioburden in your Synthes consignment trays. In particular, you keep finding it in your drill guides. Your department manager or director has been called to the OR on a number of occasions and confronted by angry surgeons, disappointed OR staff, and administrators who keep wanting to know why this problem keeps happening. But you are at a loss. You’ve had staff meetings about it, called in Synthes representatives to in-service your staff, posted photos of the problem instruments all over your department, and dirty drill guides are still making their way through the process to the patient. What gives?

Well, if your team has the desire to clean the drill guides appropriately, and they’ve had all the education necessary to do so, has anyone stopped to see if they have the right tools to get the job done? What is the diameter of all the drill guides your technicians have to clean? Do you have brushes that are small enough to go inside, but still large enough to get proper contact and friction in the cleaning process? Do you have proper chemicals, dosers, and timers to ensure a proper detergent soak? Is there even enough lighting at the sinks to see what you are trying to do? If you can’t answer these questions confidently, then the Triangle of Truth may be telling you that your team is not equipped to meet your expectations

No Knowledge: On assumptions and accidental ignorance (scenario 2) Something is going on with your laparoscopic instrument process. Every now and then, you get a call from a surgical technologist who says she noticed a nick or crack in a laparoscopic grasper in one of their cases. That doesn’t make a lot of sense because everyone in your department knows to complete laparoscopic insulation testing and detailed inspection on every device, every time. Or do they?

As you work your way through the Triangle of Truth and begin asking your team about the proper insulation testing process, you quickly identify a new technician on third shift who somehow missed any training or orientation regarding how, when, and why to do laparoscopic insulation testing. Even though this technician wanted to do the right thing and had the proper tools to do so, he was missing key information to get it done. Asking these questions helps identify assumptions and accidental ignorance that may be leading to broken processes and outcomes. Without proper knowledge, nothing else will work.

No Desire: On determination and decisions (scenario 3) You only have so many washer-disinfectors in your department and you have a growing number of orthopedic cases pulling in 6–10 trays per procedure. Department staff understand how and why they must separate each level of a multilevel vendor tray as it comes through the washer to allow for proper impingement contact from the washing cycle. But when you audit the process on your regular rounding, on off-shifts, and the weekend, you see a trend that the higher the loaner volume grows, the less compliance you see regarding separating each tray level when staging for the washers.

The Triangle of Truth tells you that your team has all the tools they need to separate each tray, and that they have adequate competency to understand the importance of this workflow, so the only thing left is confronting the fact that your technicians still lack the desire to consistently follow the policy. Simply put, even though they know how and have the tools, they don’t want to do it. Now, just because you pinpoint a lack of desire through this process does not mean your technicians don’t ultimately care about their jobs. It means this is where you want to target your initial conversations. Why do they feel that it’s okay to disregard their training and department policy in these situations? You may get answers across the spectrum from lack of trust in the process, limited recognition for a job well done, or any number of other causes.

Obviously, there is nothing magic about the three points of the Triangle and no one is arguing it is a fail-proof tool to solve every issue that may come your way in a sterile processing department. But the Triangle of Truth is an easy, memorable filter to help team members, both staff and leaders, better communicate with each other regarding broken processes and get to the heart of personnel issues without making unhelpful assumptions. Leaders must properly equip their teams with the tools (#1) and training (#2) necessary to complete their daily tasks, and technicians must cultivate a desire (#3) to own it.

That’s the truth, and I’m sticking to it.

What say you?

Hank Balch is the Founder and President of Beyond Clean, the global leader in Sterile Processing education & networking. You can follow him on Linkedin at Hank Balch and find his Fighting Dirty video series on YouTube. Hank is an international thought leader and has written over 200 other Sterile Processing articles and commentary, along with published articles in Becker's Hospital Review, Infection Control Today, AAMI News, AAMI BI&T Journal, Outpatient Surgery Magazine, and contributions to Healthcare Purchasing News. Hank's CS/SPD team in Louisville, KY was named the "2016 CS/SPD Department of the Year" by HPN. He has also served as the founding President of the South Texas Association of Sterile Processing Services and President of the Kentuckiana IAHCSMM Chapter, in additional to being nominated for the 2017 President-Elect & 2018 President-Elect of the International Association of Healthcare Central Service Materiel Management, now HSPA.

Comments